Enhancing Manufacturing Operations!

In today’s rapidly evolving manufacturing landscape, embracing digital transformation is paramount for staying competitive. One key aspect of this transformation is adopting Manufacturing Documents Management & Control Software—a digital toolkit designed to revolutionize how factories manage their crucial documents. Think of it as a savvy assistant for factories, creating a secure digital hub where vital papers can be created, stored, organized, and accessed with ease. It not only ensures everyone has the right information at their fingertips but also acts as a vigilant guardian, ensuring that industry standards and safety regulations are rigorously followed. This software becomes an invaluable companion in the complex world of manufacturing, streamlining processes and fortifying compliance.

However, according to a report by Nintex, a staggering 58% of employees waste at least an hour per day navigating outdated document management systems. This lost productivity can translate into significant financial losses over time. Moreover, a study by the International Data Corporation (IDC) underscores the cost implications of legacy systems, revealing that their Total Cost of Ownership (TCO) can be up to 3-5 times higher than modern, cloud based solutions. This includes hefty expenses associated with maintenance, support, and integration. In the following sections, we’ll delve into the specific consequences of relying on legacy software and explore how modernizing with a document management software can offer a competitive edge in the manufacturing realm.

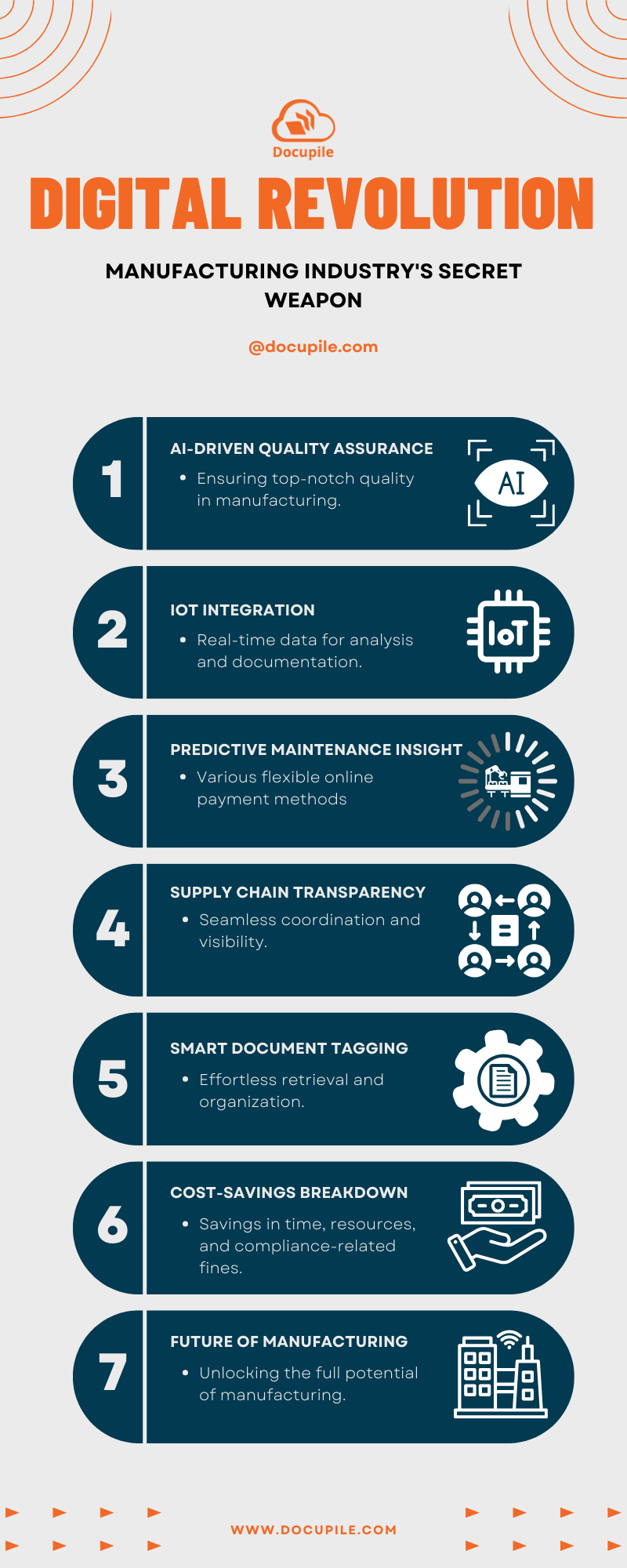

At a Glance:

Here is a Cool Infographic!

What is Manufacturing Document Control Software?

Manufacturing Document Control Software is like a smart tool for factories. It helps keep all the important papers in one digital place. You can make new documents, save them, and keep them organized. It also makes sure everyone has the right info they need, and it helps follow the important rules for making things safely and correctly. It’s like a helpful friend for factories!

Consequences of Using Legacy Document Control Software for Manufacturing:

Using old document software in manufacturing can cause big problems. These old systems don’t have the fancy tools needed for today’s factories. Here are some things that might happen:

To fix these problems, factories should think about using modern document control software. This new software has better tools, security, and can work well with other systems. It helps factories keep up with the fast-changing world and make things better and safer.

How Does it Help in Managing Manufacturing Documents?

Using document control software can provide several significant benefits to manufacturing industries, helping them streamline operations and enhance overall business performance. Here are some key reasons why manufacturing industries should consider implementing document control software:

In summary, document control software plays a crucial role in improving efficiency, compliance, and overall performance in manufacturing industries. It helps organizations maintain accurate, up to date documentation, mitigate risks, and streamline operations, ultimately leading to higher-quality products and a competitive edge in the market.

Digital Transformation with Manufacturing Document Management Offers Competitive Edge

Using Digital Transformation with Manufacturing Document Management gives companies a big advantage. Here’s how:

Digital systems speed up processes, making things happen quicker. They can give helpful information from data, helping make better decisions. People can work together easily, even if they’re far apart. It encourages creativity and problem solving, leading to fresh solutions. Important information stays protected, so everyone can trust it. It works well with other business tools, making everything run smoothly.

So, going digital with Manufacturing Document Management isn’t just about paperwork—it’s about working smarter and gaining a real edge in the industry.

SOP Conformity & Manufacturing Document Control Software

Standard Operating Procedures (SOPs) are fundamental documents in manufacturing industries, as they outline the step by step instructions for carrying out specific tasks or processes. Ensuring that SOPs conform with manufacturing document control software is crucial for maintaining operational efficiency and compliance. Here’s how manufacturing document control software can support SOP conformity:

By using to manufacturing document control software, SOPs become living documents that are efficiently managed, updated, and adhered to. This not only ensures operational consistency and compliance but also contributes to overall process improvement and product quality in the manufacturing industry.

BOM Management & Manufacturing Document Control Software

Document control software plays a crucial role in managing Bills of Materials (BOMs) in the manufacturing industry. Here are several ways in which document control software supports BOM management:

By using document control software for BOM management, manufacturing companies can ensure that their products are built according to the most current and accurate specifications. This leads to improved product quality, reduced errors, and increased efficiency in the production process. Additionally, it helps maintain compliance with industry standards and regulatory requirements.

Digitize Your Process & Be Future Ready!

In the fast evolving realm of manufacturing, using modern Document Management Software isn’t just a wise choice—it’s a strategic advantage. The numbers tell a compelling story: legacy document management systems can lead to significant losses in time and resources. Legacy systems often come with a hefty Total Cost of Ownership, far surpassing their modern counterparts. This puts focus the urgency of making the transition.

In the pursuit of operational excellence and compliance adherence, a transformative solution quietly takes the lead. Seamlessly integrating into manufacturing processes, it serves as a dedicated partner. Its advanced features and user friendly interface are custom made to meet the intricate demands of modern factory environments.

With this ally in place, factories are poised to browse through the complexities of modern manufacturing with confidence. It’s time to step into an era of efficiency and precision, where success is not just a possibility, but a promise. In this pursuit, Docupile stands ready to lead the way.